Ground markings separate traffic lanes and guide aircraft; without them there would be chaos on roads and runways. They have very varied appearances – sometimes they are continuous, sometimes interrupted and sometimes even dotted – and usually white or yellow. Marking technology “Made in Germany”.

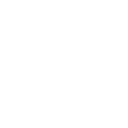

The world market leader in marking technology is Hofmann in Rellingen, whose 100 employees supply customers in 150 countries. HEROSE has been the company’s regular supplier for more than 20 years. Manfred Kadner is the HEROSE sales representative responsible for this customer: “They need our type 06205 and 06380 safety valves” Torsten Pape, the Hofmann Sales and Marketing Manager explains their use: “They secure the pressure vessels of the compressors, which have a pressure of up to seven bar.” Pape only has good things to say about the cooperation between the two companies: “The quality of the valves is excellent, and over many years we have built up a trusting cooperation.”

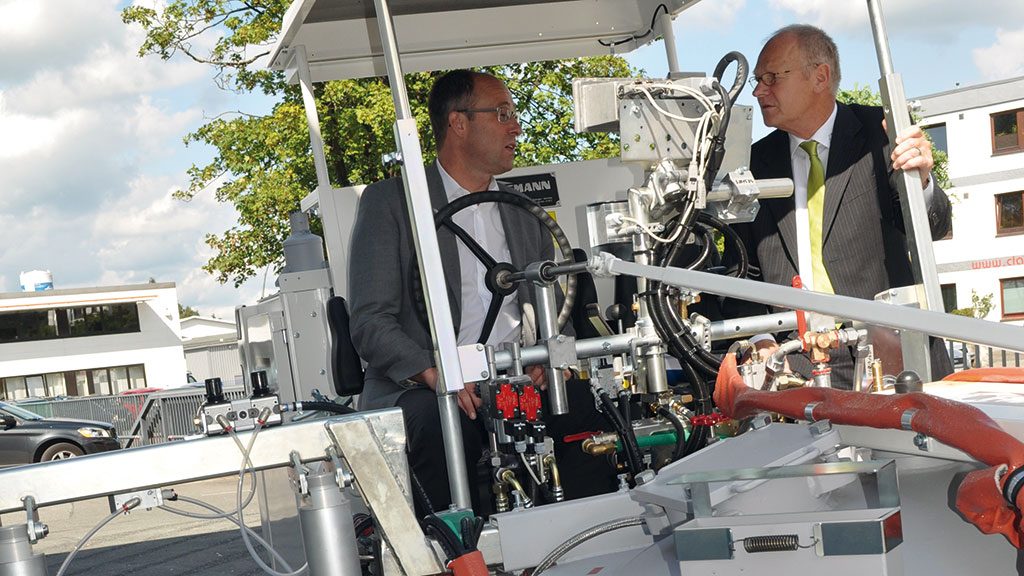

The range of Hofmann products includes everything which is needed for marking; starting with small, manually guided machines which are the size of children’s prams up to self-propelled riding machines and trucks with attached marking equipment. The range also includes drying and marking removal machines as well as melting systems for thermoplastic materials, which are applied to the ground. “Each of our machines is an individual item”, says Pape, “which means that we are more expensive than our competitors.” However, Hofmann offsets this with good service. Eight technicians travel around the world to explain new machines and repair old ones. In addition to the label “Made in Germany” this after-sales-service is the most important sales argument. Because of this, senior director Frank Hofmann (75) and his son Jan (40) have never considered relocating production abroad.

Roads and traffic lanes are rarely separated with just paint. “That would wear off very quickly”, says Pape. Usually, plastic is used. The ingredients are mixed on site – either cold or heated to about 220 degrees – and sprayed directly onto the road. When it dries, the material becomes rock hard. The glass beads on the surface are very important: “The round beads reflect light and ensure that the lines can also be seen in the dark and wet”, explains Sales Manager Torsten Pape. Because of this, each marking is coated with beads of up to 2.5 millimetres in diameter. One of the largest manufacturers of these beads is Swarco in Austria.

Whether hot or cold, thick or thin lines, dots or dashes: The main question for every road marking is how it can be applied to the road surface so that it lasts as long as possible. The answer is different, depending on the climate zone. Pape: “In hot countries markings tend to be applied hot. In Germany, cold plastic is mainly used.” If possible, the hot plastic must remain at 220 degrees until it comes into contact with the asphalt, otherwise the bond between the two materials is not optimal and the marking soon flakes off. Pape: “Even on its way from the machine to the ground the plastic cools down a lot, so it has to be even hotter beforehand. Because of this, the feed hoses are surrounded with oil at 250 degrees.” In order to maintain its position as world market leader in marking technology, Hofmann places a high priority on its own development work. At present, eleven employees are concerned with tomorrow’s topics. Pape describes two of these: “For one thing, we are working on structured markings with built-in drainage, which allows rainwater to run off to ensure good visibility even in bad weather. We are also continuously improving the vibration effect of the lateral lane markings.” In Germany, these layers can be up to seven millimetres thick – a thickness which will immediately wake up even the most exhausted truck driver.

Hofmann does not just produce marking machines. It has also gained a reputation as a trendsetter in the industry. Since 2001 the company has offered a forum in the form of an annual Technology Day to promote the dialogue between marking companies, material manufacturers, authorities and ministries, as well as research and education. Pape: “In November, about 600 guests from 45 countries will meet again here – everyone who is well-known in our industry.” The specialist lectures will be translated into five languages by simultaneous interpreters and new machines and ingenious technologies will be presented on various stands.

Hofmann in Rellingen is happy with the current market situation. More than 100 large machines are produced each year, with prices between 60,000 and 400,000 Euro. “Just recently, the demand from Latin America and Africa has greatly increased”, says Pape. 60 percent of the production is now sold to countries outside of the EU. By far the best-selling marking machine is the H 33 model.

Even with the aid of all this technology Hofmann machines cannot steer straight on their own. Although sighting devices help the driver to navigate, ultimately it is the skill of the operator which determines whether the line is right.

Pape considers the success of the company, which was founded in 1952 to be due to fact that even today, the company is family-owned and everyone knows and respects each other. “What we achieve here with 100 employees is really great. We are a super team with hardly any hierarchies and most of our employees have been with the company for many, many years.”

Photos: kitzcorner – Fotolia.com (at the top), Hofmann GmbH, Carsten Wurr

Read the current digital customer magazine now!

Read the current digital customer magazine now!